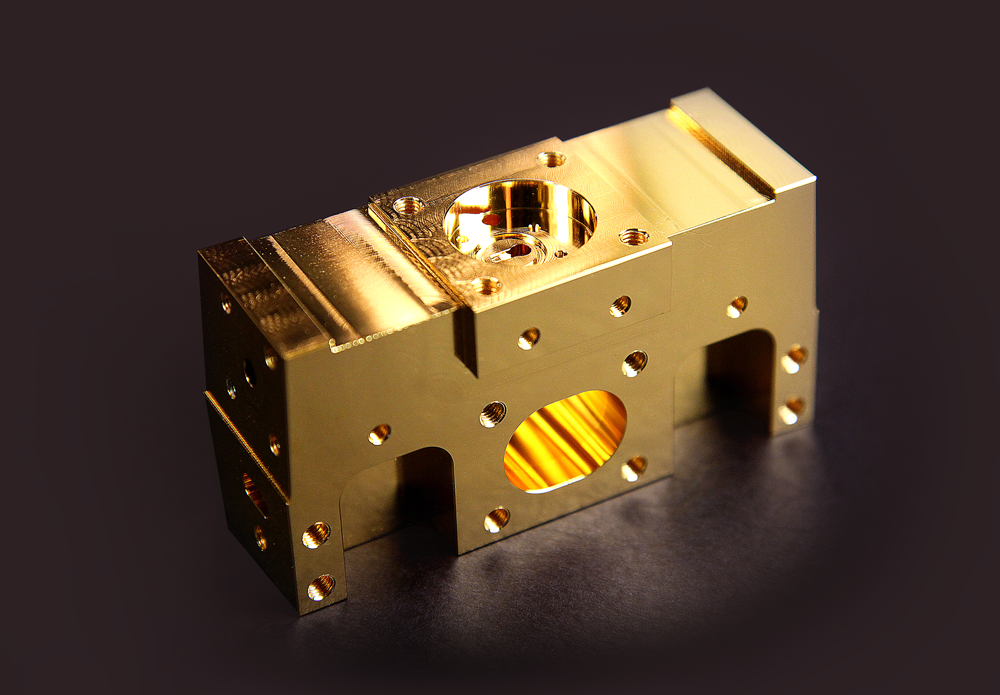

A gold coating is in many applications superior: it conducts electricity reliably, withstands corrosion and retains its properties even in demanding conditions. The challenge comes up when the coating is subjected to repeated abrasive loading – traditional hard gold is excellent in many ways, but its wear resistance is limited in certain targets that include “friction and switching”.

Eforit Oy’s NanoDAu™ is a solution developed for this: an electrolytic gold-plating process in which nanodiamonds co-deposit into the gold matrix. The result is a gold coating that is clearly more wear-resistant and at the same time lower in friction – without electrical conductivity or appearance suffering.

What is NanoDAu™?

NanoDAu™ is Eforit Oy’s developed and registered product name for an electrolytic gold-plating process containing nanodiamonds. The typical size of the nanodiamonds in the coating is about 2–6 nanometres, and they co-deposit as part of the structure of the gold coating.

Within the framework of the Finnish Funding Agency for Technology and Innovation Tekes’ Functional Materials programme, Eforit studied the effect of nanodiamonds in gold electrolysis, and based on the measurement results the wear resistance improves remarkably: with even half thinner layer thicknesses the same corrosion- and wear-resistance properties can be achieved as with normal hard gold plating.

What do nanodiamonds do to a gold coating in practice?

The idea of nanodiamonds is to strengthen the gold matrix on a microscopic level. When the diamonds co-deposit into the coating, they act as wear-bearing and friction-reducing reinforcers of the microstructure.

In Eforit’s own Taber wear tests, the wear resistance of the NanoDAu™ coating increased about 2–3-fold compared to traditional hard gold plating, and tests carried out by Tampere University of Technology confirmed results in the same direction.

In addition, another, in practice very significant advantage was observed: the coefficient of friction decreased to about half compared to conventional hard gold. At the same time, with four-point measurements it was found that electrical conductivity remained as good as with a hard-gold coating, and the appearance also remained similar to hard gold plating.

From Eforit’s perspective, the matter is well summarized by expert Lauri Virta:

“Hardness does not change very essentially compared to hard gold, but wear resistance becomes approx. 2.5–3 times better compared to a normal hard-gold coating, i.e. it gives a significantly greater wear and service life in targets where there is an abrasive part on the coating. The coefficient of friction drops to almost half compared to hard gold when tests were done at TUT.”

And why does this happen?

“Nanodiamonds work so that they co-deposit into the gold matrix, i.e. they come into the coating along with it. They give wear resistance and reduce the coefficient of friction.”

What benefit does NanoDAu™ bring to the customer?

When the coating withstands wear clearly better and friction is smaller, the effect can be seen directly in operating costs and in the usability of devices:

- Longer maintenance intervals and longer lifetime – especially in targets where the coating is “eaten” mechanically by switchings, sliding contacts or rotating contacts.

- Possibility for a thinner layer thickness – with even half thinner coating it is possible to reach corresponding corrosion and wear resistance properties, which helps in overall optimisation (weight, tolerances, material use).

- Better reliability in critical contacts – when friction decreases and wear slows down, the contact surfaces stay operationally reliable longer, which is often decisive for the reliability of the whole system.

- Savings and environmental benefits – longer lifetime and rarer maintenance mean fewer downtimes, fewer replacements and more efficient use of resources.

Where is NanoDAu™ at its best?

NanoDAu™ is a technical gold coating for the most demanding wear targets. Below are typical applications where the properties quickly produce real value.

1) Electronics connectors and contacts with repeated switching

In the electronics industry, for example the gold connectors of circuit boards and the contact surfaces of test equipment are subjected to constant connecting and disconnecting. Exactly in such targets traditional hard gold can wear surprisingly fast, and NanoDAu™ can extend service life significantly.

“The applications where these were thought of are mainly electronics-industry applications, e.g. in testing of circuit boards the gold connectors of circuit boards. They are pulled repeatedly, so normal hard gold wears from them quickly and NanoDAu gives them a much longer service life,” Virta says.

2) Slip rings and rotating contacts (e.g. radar technology)

Rotating contacts are a classic wear target: motion is continuous, maintenance can be expensive and an outage can be a critical risk. Eforit has highlighted especially the slip rings of radar devices, where wear resistance and lower friction can extend maintenance and replacement intervals.

“The radar rings of radar devices are also a suitable application, because gold-plated radar rings always have to be renewed,” Virta explains.

3) Marine and industrial applications where there are sliding surfaces and wearing motion

When conditions are demanding and changing or maintaining components is laborious, the lifecycle advantage of the coating is emphasised. As an example, turning propellers of ships have also been brought up, where the wear of gold-plated parts like a sliding rod can be a problem.

When can traditional hard gold still be more sensible?

NanoDAu™ is not always the right answer, but specifically a solution for targets where wear and friction define the success of the coating.

The clearest minus of the NanoDAu™ coating is cost: nanodiamonds are expensive and the continuously rising price of gold affects the big picture. Therefore, if the component in practice is not subjected to abrasive loading (or use is very occasional), traditional hard gold can be a more cost-effective choice.

Do you want to evaluate whether NanoDAu™ suits your components?

If you have a target where:

- there are many switching repetitions,

- sliding contacts or rotating contacts wear,

- maintenance is expensive or downtime is critical,

…NanoDAu™ can be exactly that small coating change that shows up as big savings and better operational reliability.