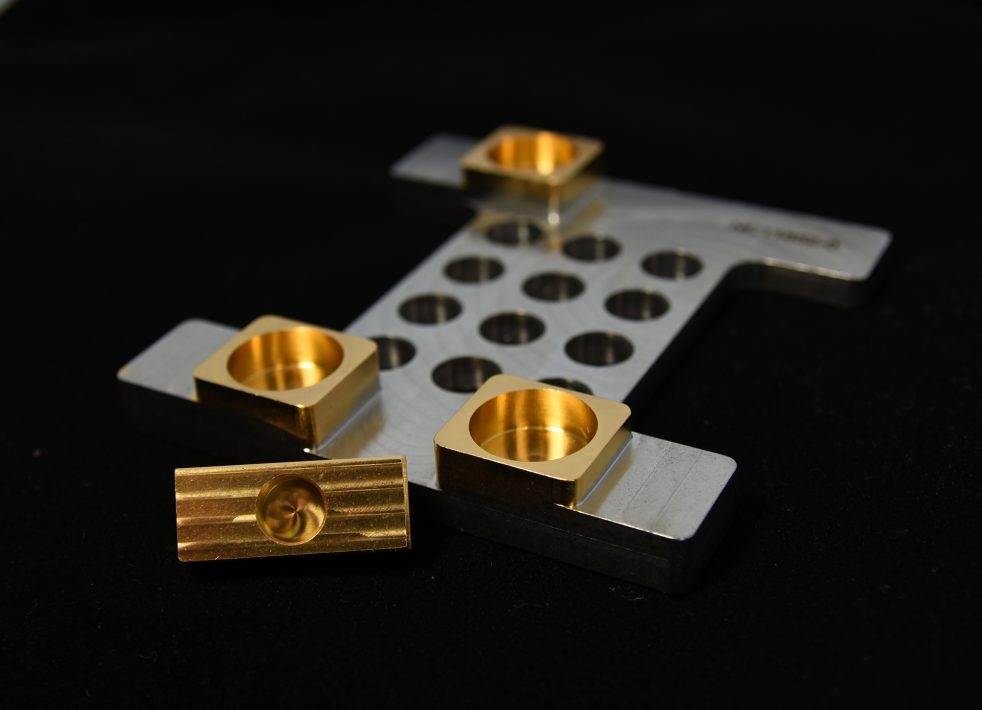

Gold plating

Gold (Au) is an excellent choice for components that require good corrosion resistance. Gold plating helps to prevent oxidation of the component, which significantly improves electrical conductivity.

The infrared reflectivity of gold is one of the best among all metals. This property is utilised in the measuring instruments of environmental technology.

Gold plating is suitable for various base materials

We offer the following gold COATING:

Hard gold

- The gold content of the coating is about 99.8 %

- About 0.15 to 0.20 % of cobalt co-precipitates, which gives the coating hardness

- The hardness is about 150 HV (Vickers)

- Recommended for applications requiring a reasonable wear and tear

- The most widely used gold plating

Soft gold

- The gold content of the coating is about 99.9 %

- The hardness is about 90 to 100 HV

- Used e.g. in electronic assemblies where the components are connected to each other by ultrasonic welding, so-called bonding method

- The name bonding gold is also used

Gold electroplating on a nickel layer

We have developed innovative coating solutions for the technology industry for almost 40 years.

We are happy to help you choose the best-suited coating for your application and as a guarantee of our quality, we can provide an X-ray analyser measurement certificate.